The 2nd Desalination Plant

With a daily capacity of up to 70 million gallons (or 318,500 m3 ) of water, Tuaspring Desalination Plant supplies PUB with desalinated water over a 25-year period.

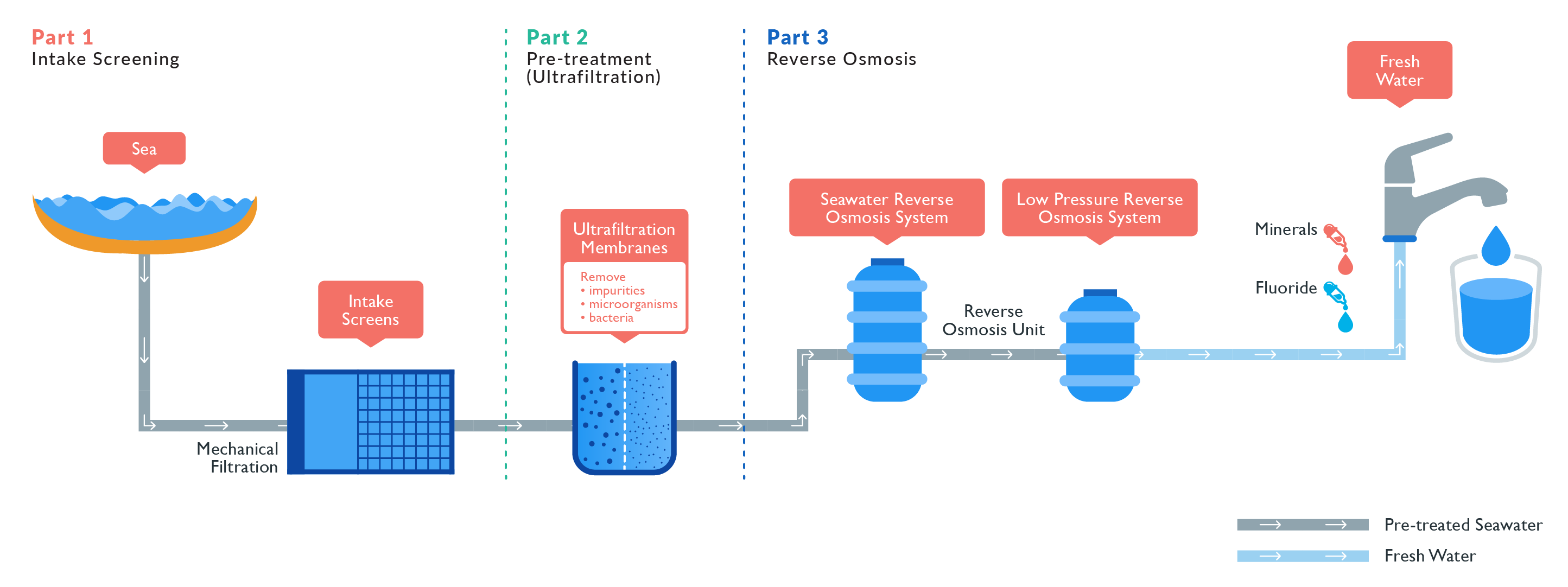

Tuaspring Desalination Treatment

View enlarged version >>

Part 1: Intake Screening

As seawater flows into the plant, sediments like seaweed and other large debris are removed via mechanical screens. Chlorine is added to hamper marine growth in pipes and other structures in the system.

Part 2: Pre-treatment (Ultrafiltration)

The ultra-filtration membranes remove impurities, microorganisms and bacteria in water, which can foul the downstream reverse osmosis system.

Part 3: Reverse Osmosis

Reverse osmosis is a critical step in the desalination of seawater. After removal of impurities and suspended particles, water is pumped through the semi-permeable membranes at high pressure. Only water molecules can pass through the membranes at this stage.

Finally, after reverse osmosis, the water is re-mineralised and stored in PUB's service reservoir before it is distributed to homes.

Prime Minister Lee Hsien Loong officially opens Tuaspring Desalination Plant, Singapore's second and largest desalination plant. From left: Permanent Secretary (MEWR) Choi Shing Kwok, PUB Chairman Tan Gee Paw, Minister for the Environment and Water Resources Vivian Balakrishnan, Prime Minister Lee Hsien Loong, 2nd Minister for the Environment and Water Resources Grace Fu, PUB Chief Executive Chew Men Leong, and Hyflux Executive Chairman and Group CEO Olivia Lum.

For latest information on Tuaspring Desalination Plant. Please click

here.