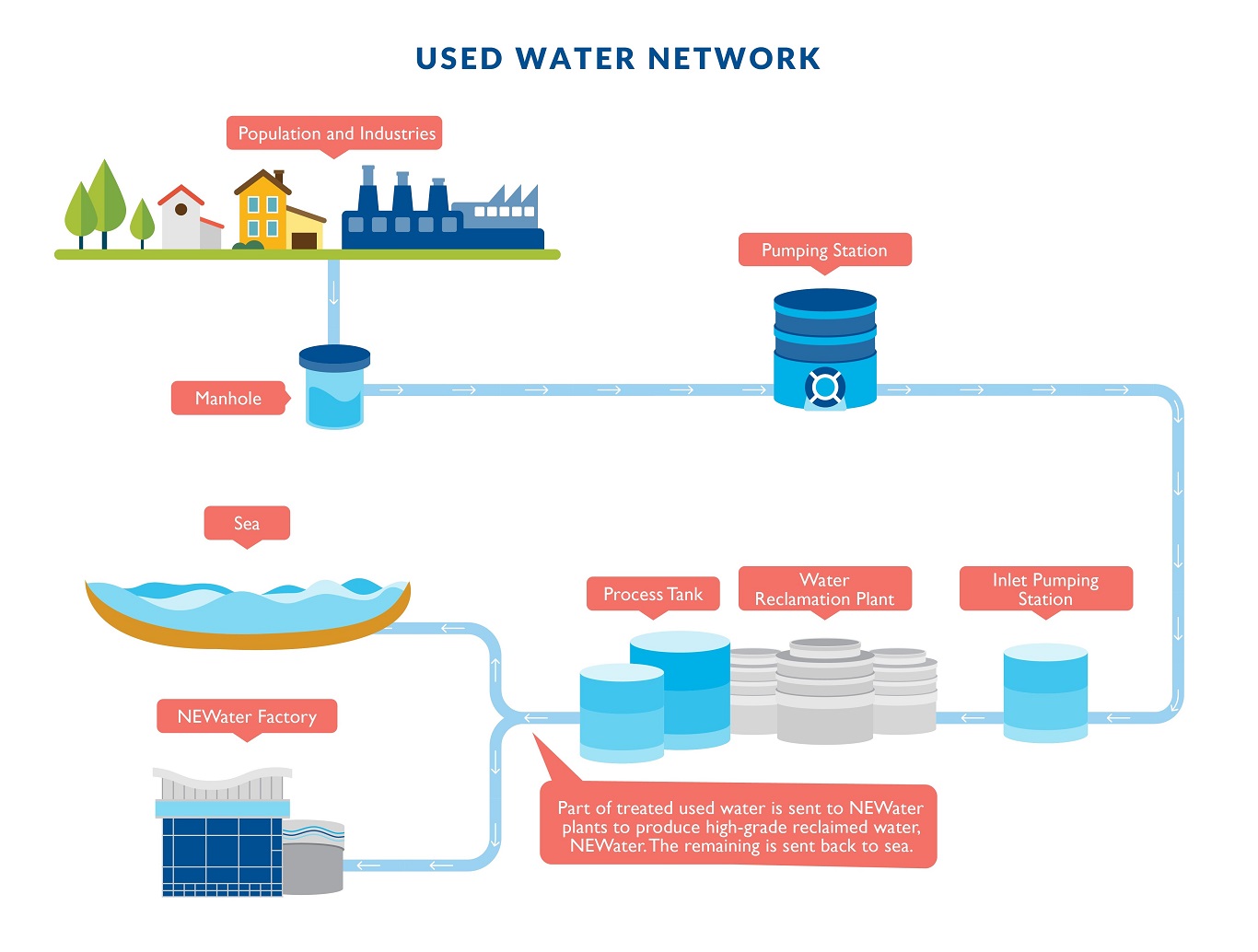

Used water from households, industries and commercial premises island-wide is collected and transported via an extensive sewerage reticulation system for treatment at water reclamation plants (WRPs).

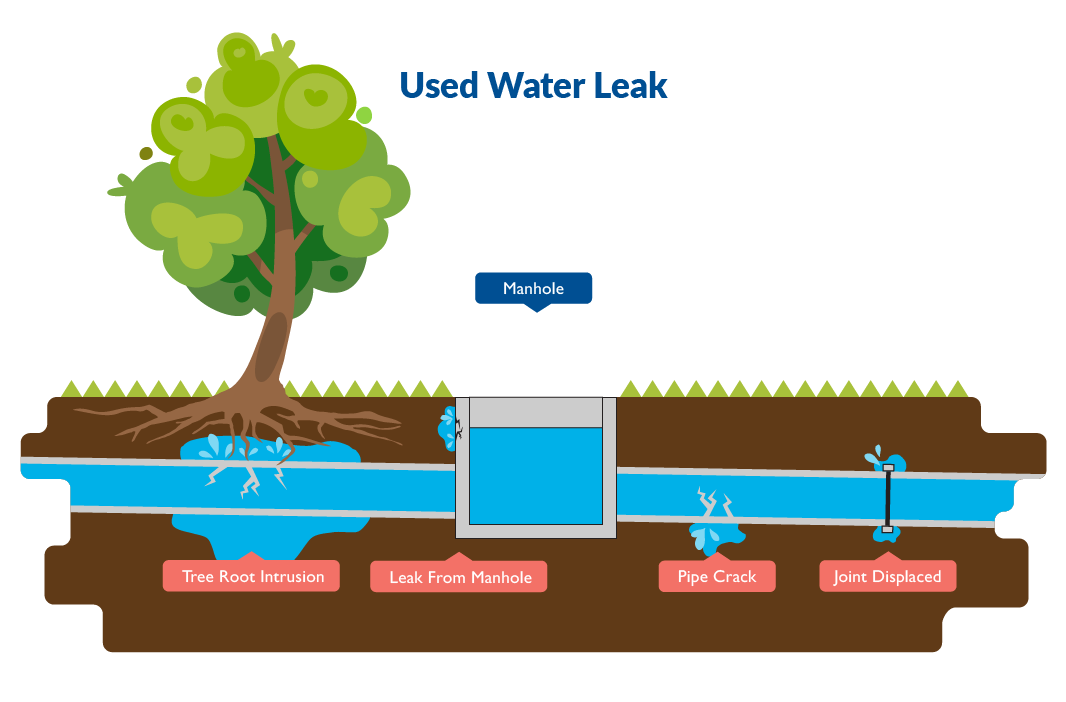

As part of the maintenance regime, PUB conducts systematic checks and carries out repairs on defective sewers to restore their structural integrity, extend their useful life and reduce infiltration and exfiltration.

View enlarged version >>

Over the years, old sewers may suffer damage from wear and tear, ground movement and tree root intrusion. This may result in leakage from the sewers into the environment, polluting waterways, canals and reservoirs. Although raw water in reservoirs is treated at water treatment plants to international quality standard before it is delivered to consumers, used water leakage to waterways and reservoirs poses aesthetic and recreational concerns.

View enlarged version >>

PUB ensures the structural integrity of the sewer network with systematic checks and repairs on public sewers across the island. Download Simple Guide on Used Water, Sewerage System and Related Applications [PDF].

How does sewer rehabilitation work?

There are various ways to repair defective sewers. If the sewer pipe is in very poor condition (e.g. collapsed sections; excessive dislocated joints, etc.), there may be a need to excavate long and deep trenches and replace it with a new sewer pipe.

For most of the defective and aging sewers, sewer rehabilitation using trenchless technology is carried out to reline the sewers and this method does not involve any open excavation works. This minimises disruption and inconvenience to the public, owners and residents.

The illustrations below show our three most common trenchless relining methods:

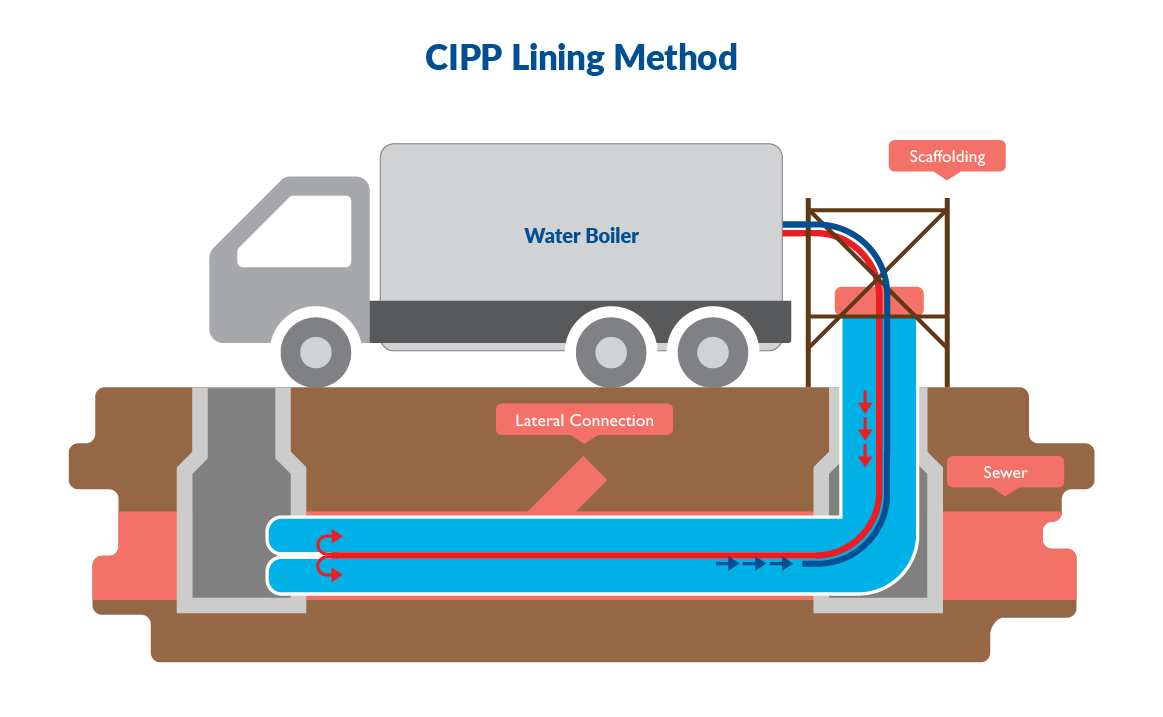

CIPP Lining Method

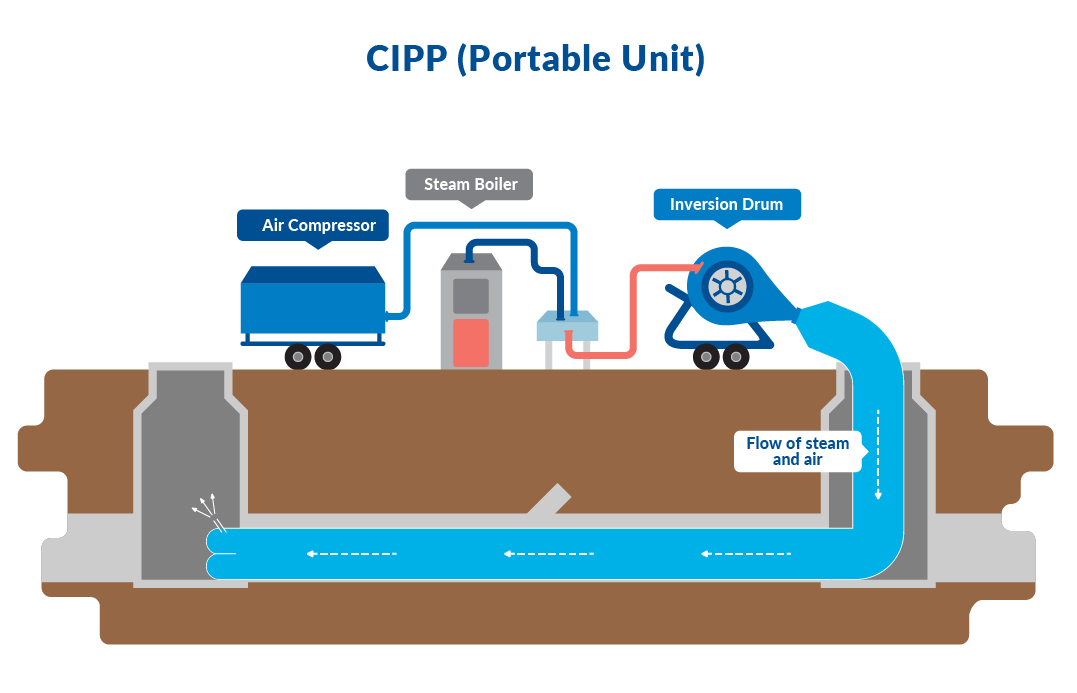

Cured-in-place pipe (CIPP) Lining Method

– It involves the insertion of a flexible lining impregnated with a thermosetting resin into a cleaned pipe using an inversion process (hot water or steam curing).

View enlarged version >>

Using water tower (by means of the scaffolding) for the inversion.

View enlarged version >>

Using the inversion drum for the inversion. This portable unit is suitable for those places with space constraints.

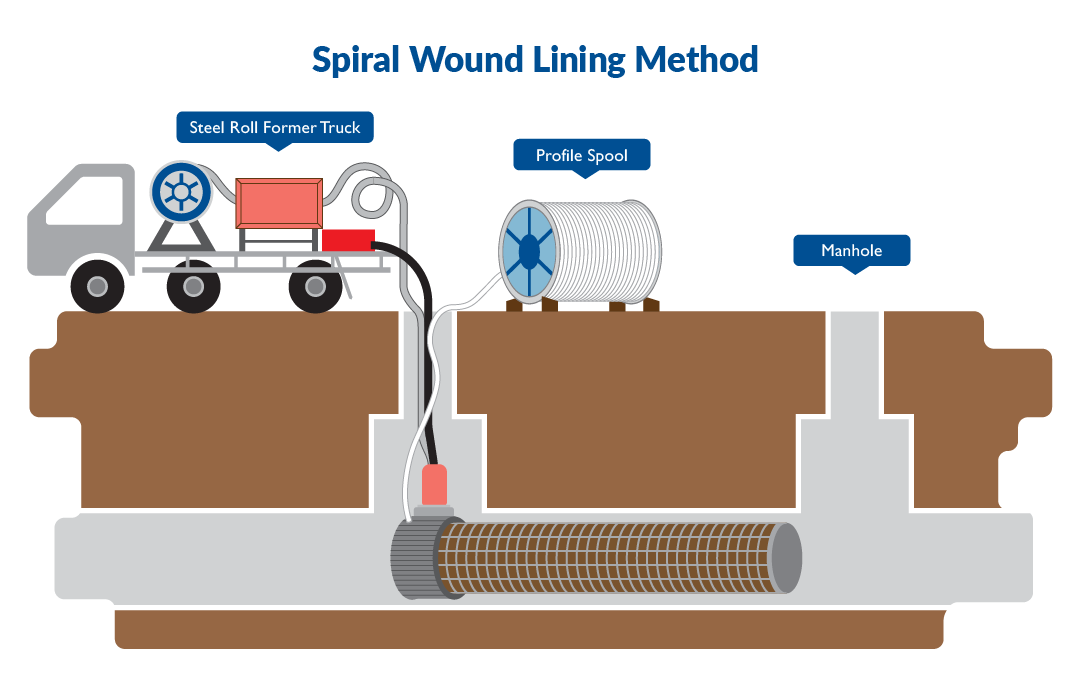

Spiral Wound Lining Method

Spiral Wound Lining (SWL) Method

– It involves winding of interlocking PVC strips in a spiral pattern through the manhole to form a new pipe within the existing pipe.

View enlarged version >>

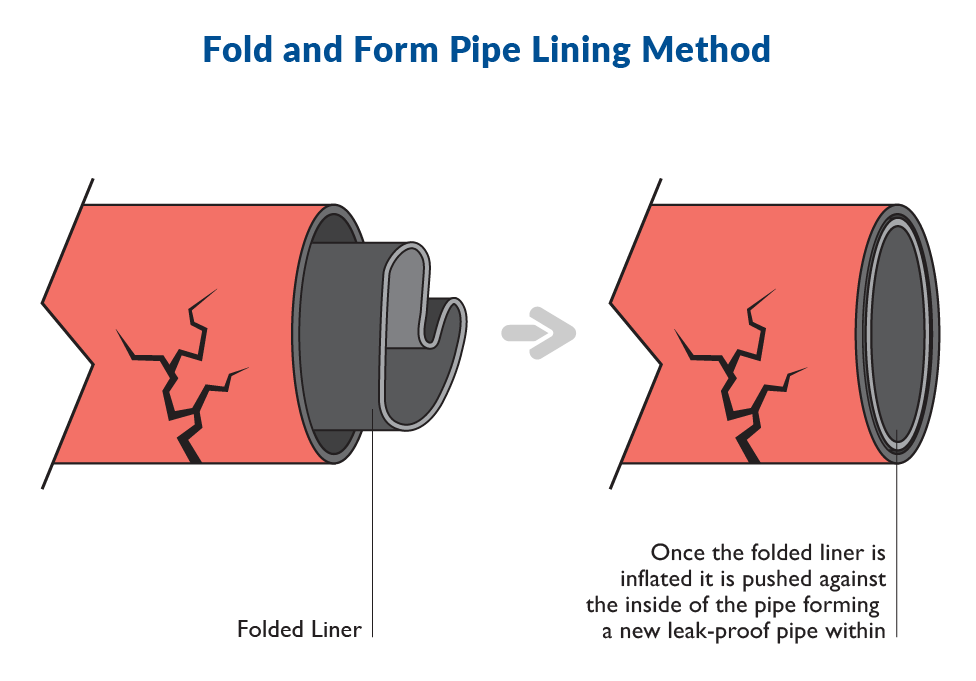

Fold and Form Pipe Lining Method

Fold and Form (F&F) Lining Method

– A continuous coil of pre-fabricated PVC pipe in a "folded" shape is pulled through the existing pipe, and steam is used to expand it back into its original circular shape. When cooled, it forms a tight-fitting liner within the existing pipe.

View enlarged version >>